Gardening 101: Vertical Farming In The Metroplex

NORTH TEXAS (CBSDFW.COM) — Farmers growing food for the rest of population is one of the necessary bedrocks for any civilization. We can't get things done unless we eat. The United States has a population of 330,000,000 people feed by food imports and about two million U.S. farms. Approximately 20,000,000 Americans and immigrants, about 10% of the workforce, work in jobs related to the agricultural and food sectors.

As the U.S. and world population continues to climb shifting climate conditions and rising seas are making feeding all of us more challenging. It is estimated that the world population will reach nearly 10 billion people by 2050. To feed that many more people will require world farmers to increase yields by almost 70% over the next 30 years. There isn't the farmland to spread out horizontally to meet that challenge. Plus are also increasing problems with underground water supplies, fertilizer run-off and soil loss.

What are we to do? Go inside and go up. Vertical Farming is one of fastest-growing sectors in ag-business. Vertical farming operations can spin-up an operation just about anywhere, including inside urban areas where transportation of garden greens is reduced to local delivery instead of trans-state railcars.

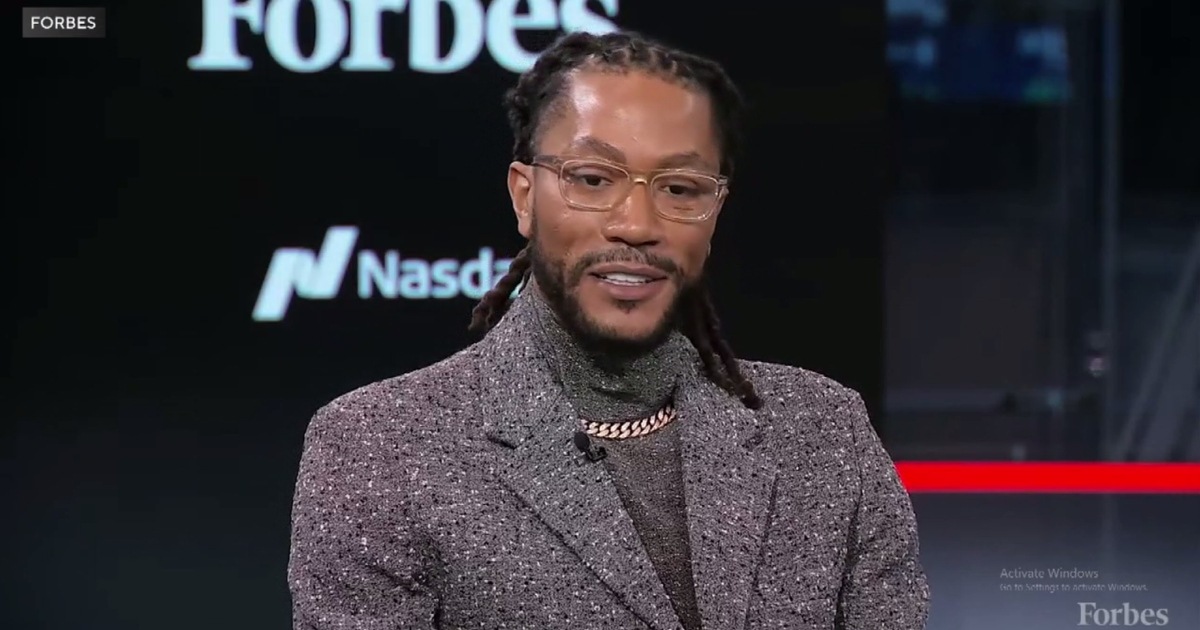

I visited Green Eden Technology in Cleburne to see where the science is right now. If you are heading south on the Chisholm Trail Parkway, just north of town at the Sparks Road exit look to your right. Across the street from the massive Walmart Warehouse sits a series of greenhouses, they are easy to spot in the early evening in their florescent glow from the grow lights. Aaron Fields is the Director of Horticulture; he took us on a tour of the facility. Currently it barely uses half of its capacity for Romaine lettuce shipped to local stores. The rest of the space is used for testing and development. This is not only a commercial farm it's also a working research lab. A big part of their business model is selling the "how" of vertical, hydroponic farming. And the model is working. A grocery retailer is building a next generation greenhouse next to Eden's three-year-old facility. It should be fully operational by early summer. Eden Green will manage the greenhouse using technology and techniques perfected in their current vertical farm operation.

The Eden Green greenhouse sits on just an acre, there is room on their property to build dozens and dozens of more buildings just like it. They hope grocery chains, private investors or restaurant groups will want to build their own farm on their site. Eden Green Technology will grow their staff of farmers to meet the demand. Data input has replaced the plow. Lab coats have replaced overalls.

After our tour we were presented some of the fresh greens grown in the warehouse. Since they had just been picked, the lettuce stayed deep green and crisp in my refrigerator a full week later with zero degradation. The lettuce is extremely flavorful; the plants energy goes to its leaf and not an extensive root structure to anchor into itself if it had been grown in dirt. The roots on this plant could easily fit in a paper towel roll and looked more like a narrow band of wet hair then a root ball.

Think about it. Instead of a growing season there are rows and rows of your crop at different stages of development. As a farmer you are not fighting bug infestations, severe weather or drought. You produced a weekly crop year-around in perfect growing conditions. You use 95% of the water a traditional outdoor row crop would demand. Plus you don't have to worry about all the bacteria problems associated with the soil and water you use. There is no soil in vertical farming and there is very little water. The one-acre warehouse in Cleburne grows thousands of plants a week and uses about as much water as two households. The future of growing food indoors is looking up.