How Lego makes its Lego bricks

If you're a Lego fan like me, visiting this little town in western Denmark is a little like making a religious pilgrimage. That's obviously an overstatement, but this is the home of Lego, maybe the world's most famous toy. I got a chance not only to visit the company's headquarters but also to see the production, processing, and packaging of the famous bricks.

The whole process is actually quite simple. Making the bricks involves injecting very hot plastic into a mold and pressing it. Cool it a bit, open the mold, and out drops Lego bricks.

This is from the second part of the process, when bricks and other elements--such as these soon-to-be mini-figures--are finished by adding any additional parts, like legs, arms, and heads, and having anything they need printed on, like a suit and tie.

The Lego Factory

This is the reception at Lego's world headquarters. Note the way the ceiling and the chairs make up what appears to be two interlocking Lego bricks.

The Lego Factory

All Lego bricks are made from the same ABS plastic. It comes to Lego from suppliers and is held in giant silos. Generally it is clear or red, and the color for specific bricks is added at the molding machine. This is a bin full of ABS plastic, with some additional colors mixed in.

The Lego Factory

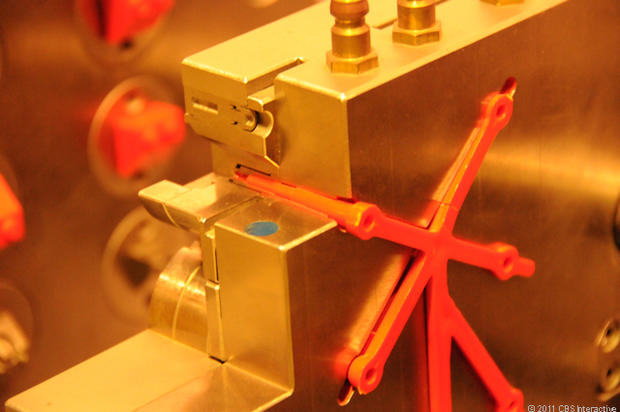

This is a cross-section of a Lego brick mold. First, very hot plastic is injected into the mold on the right side. It then spreads through little channels and is then pushed into the press area of the mold through very small slits. When cold water is then flushed through the mold, it cools down the plastic, and the mold opens, allowing the bricks to snap off and drop down onto a belt below.

The Lego Factory

Currently, there are about 7,000 active molds being used at Lego. All told, it keeps about 9,000 around, with many stored on shelves like this one. The average mold is worth $72,000, with the most valuable coming in around $360,000.

The Lego Factory

Here, we see where the plastic is injected into the press area of the mold.

The Lego Factory

Here we see two ellipsoid pieces that have just been pressed, still sitting in the mold. In a second, they will drop off and onto a belt below.

The Lego Factory

Here we see the mold for the ellipsoid pieces from the previous picture. Note the shape of the mold.

The Lego Factory

Part of Lego's system is to be as efficient as possible. That means making bricks and other elements that can be used in different ways. These blue pieces can either be used as heads for mini-figures, or as decorations for other pieces.

The Lego Factory

Thousands of purple Lego bricks sit in a bin, having just been pressed in a mold.

The Lego Factory

This is one of 12 molding 'modules' located in Billund. Each module, or room, has as many as 64 working molding machines, divided into two aisles of 32 machines each.

The Lego Factory

Here we see a robot arm inside the molding machine grabbing the waste from the injection and molding process. This plastic will be put into a grinder, and reused almost immediately.

The Lego Factory

This is a bin full of the waste plastic from each mold.

The Lego Factory

Almost none of the plastic used in the Lego factory goes to waste, but a very small amount does get spilled. This giant bin is full of spaghetti-like plastic that has hardened and has no use.

The Lego Factory

These tubes carry ABS plastic into the molding rooms. The sound coming from the pipes is very much like what millions of grains of rice would sound like going through pipes.

The Lego Factory

A mold is used for about four weeks before it is pulled from the production line and completely cleaned out. Here, we see a Lego worker doing a meticulous cleaning of a mold.

The Lego Factory

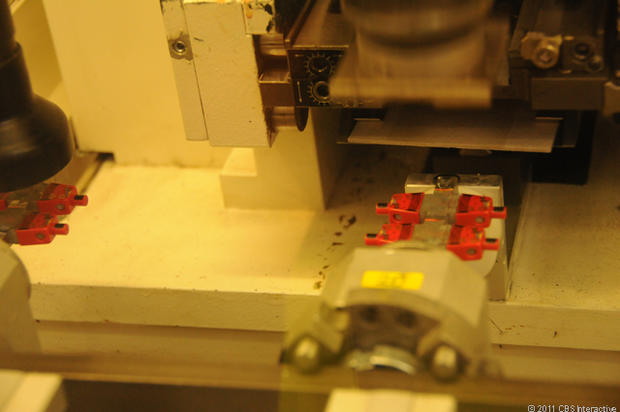

Now in the processing part of the production system, this machine is dropping torsos for mini-figures onto a belt where they will have additional elements like arms and legs and heads added to them.

The Lego Factory

Here we see a small robot adding hands to a mini-figure.

The Lego Factory

Here we see the machine stamping on printed details, such as a face, and a shirt.

The Lego Factory

This display shows the weight of a small bag of Lego bricks known as a pre-pack. The weight must be between 94.9 grams and 95.7 grams. Coming in at 94.94 grams, this back passes muster. However, as the display shows, five bags came in too light, and one was too heavy. But 5,354 were in the target range.

The Lego Factory

Here we see pre-packs going up a conveyor belt, at the top of which they will be weighed.

The Lego Factory

Now in the packaging department, most of the bricks are in packs that are dropped into a package automatically. But some of the packs are too big to fit in when dropped that way and must be shaken and flattened manually in order to fit properly.

The Lego Factory

These are hundreds of flat boxes for Star Wars Lego sets.

The Lego Factory

This machine presses down into each Star Wars set that passes through to make sure that the packs of Lego bricks inside isn't too high up. If it is too high, the box may not be able to be closed correctly.

The Lego Factory

Here we see full Star Wars boxes moving down the line.

The Lego Factory

Here, the machine automatically closes the lid of the box of each Star Wars Lego set.

The Lego Factory

Here we see full and closed Star Wars Lego set boxes coming off the packaging line.

The Lego Factory

As the Star Wars sets are finished, this machine grabs two at a time and puts them into cases of six.

The Lego Factory

Here, a Lego worker has to reach inside the machinery and grab two boxes that have accidentally been spun off the belt.

The Lego Factory

Each of these cases contains six Star Wars Lego sets.

The Lego Factory

Shrink-wrapped and ready to go, these cases of Star Wars Lego sets will be shipped to the Czech Republic, where they will be handled by a giant distribution center there operated by DHL for Lego.

Please visit the Road Trip 2011 page for all the coverage from CNET reporter Daniel Terdiman's travels through Europe.