LL Bean's "duck boot" gets a production boost

L.L. Bean wants to kick off the fall season without one chronic headache: shortages of its iconic "duck boot."

The Maine-based retailer is expanding production to keep up with demand for its leather-and-rubber duck boot with a new manufacturing center that's being unveiled Thursday. The company also plans to hire more than 100 additional production workers at two locations in Maine.

The old boot, which is also called the Bean boot, has done more than soldier on: Annual sales have grown from fewer than 100,000 pairs a decade ago to this year's projection of 750,000 pairs. The company hopes to hit the 1 million mark next year.

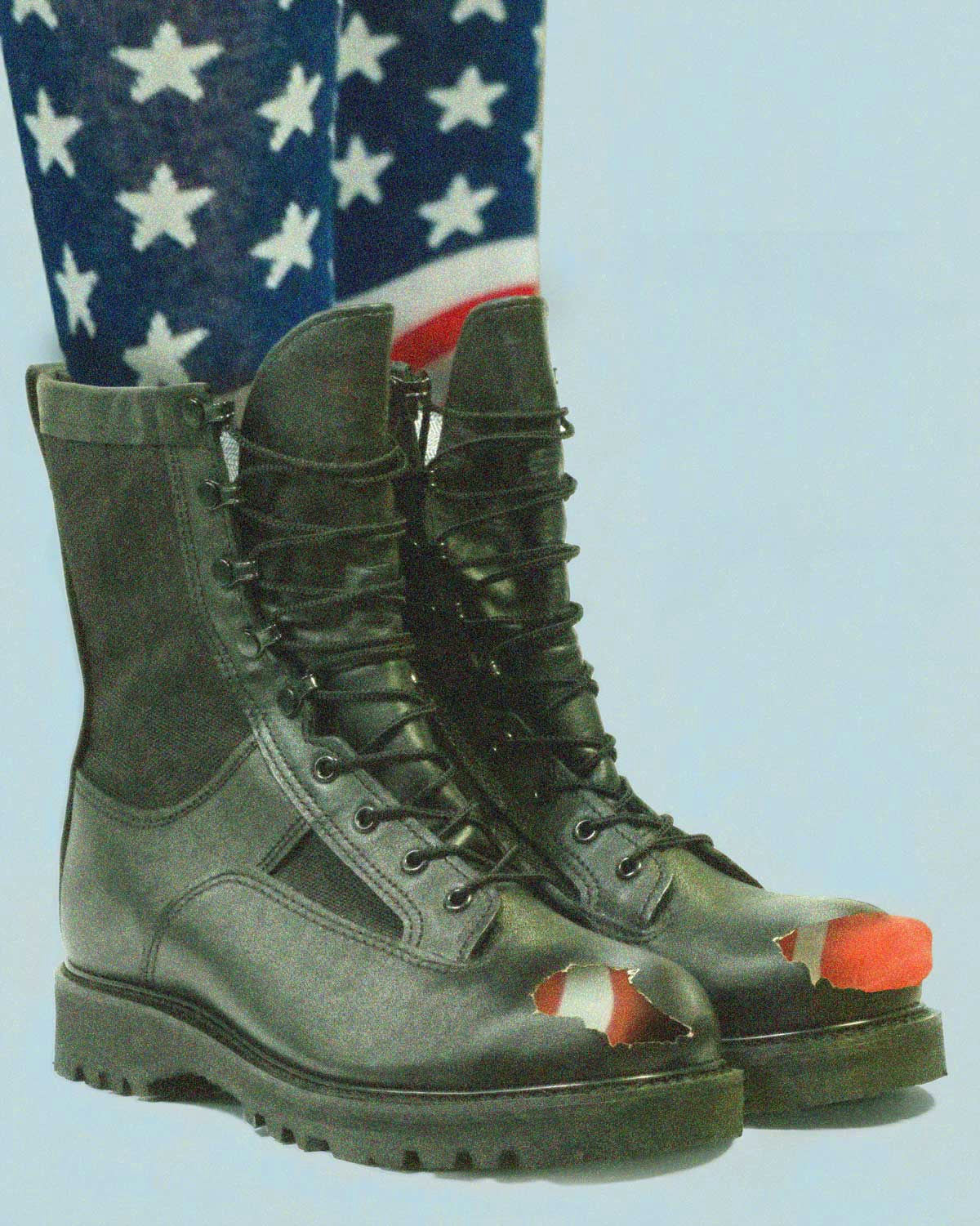

L.L. Bean has been struggling for several years to keep up with demand for the classic boot, which debuted in 1912 when founder Leon Leonwood Bean created a half-rubber, half-leather boot to keep his feet dry when he went hunting. The expanded production isn't the first for the iconic boot, as L.L. Bean two years ago hired an additional 100 boot makers and spent $1 million for a second molding injection machine to pump out more rubber bottoms.

The reason for their popularity? Fans like the boots' durability as well as L.L. Bean's 100 percent satisfaction guarantee.

The 106,000-square-foot (9,847-square-meter) building doubles the production space in Lewiston, which is home to two of the company's three injection-molding machines. The other molding machine is in Brunswick, where the leather uppers are stitched to complete the boots.

All told, L.L. Bean plans to hire about 160 additional production workers, including about 60 in Lewiston, Maine's second-largest city.

The boot is synonymous with the brand. There's a giant boot outside the main store in Freeport and there are two Bootmobiles rolling around North America. There's even a Bootmobile in Japan.

The "Made in the USA" label is rare these days. Well-known Maine brands like G.H. Bass, Sebago and Dexter are now made overseas.