Deep inside the world's longest tunnel

SEDRUN, Switzerland--I'm a kilometer inside one of the Alps and nearly 800 meters below the surface, and it's pitch black. And I'm falling at 14 meters a second.

But this isn't a story of fire and brimstone. It's a story of the construction of the world's longest tunnel, a new 57 kilometer all-flat rail line deep under the Swiss Alps that is planned to open in 2017 and which is hoped to double the capacity of cargo along the crucial Zurich to Milan line. It's also Switzerland's largest-ever ecological project.

This is the Gotthard Base Tunnel, part of a $14.4 billion effort aimed at cutting the number of heavy trucks passing over the Swiss Alps in half, while also drastically reducing the physical toll on these essential roads and slashing the amount of pollution being spewed in the region.

Photos: Shovel by shovel, building the world's longest tunnelThough ideas for a flat rail line under the Gotthard massif was first posed in 1947 and endorsed by the Swiss government in 1962, planning began in earnest in 1992. And it became a reality in 1998 with the last of five referendums (none of which got less than 65 percent approval) instituting a series of taxes--on oil, on trucks, and on people's purchases--intended to fully pay for the new tunnel system. "It's a gift of a Swiss generation to ourselves," said Yves Bonanomi, who in addition to performing geological research for the giant effort also escorts journalists, politicians, and other VIPs through the labyrinthine construction here.

I've come here as my first stop on Road Trip 2011, and trusting Bonanomi to deck me out in the standard down-below uniform of bright orange coveralls, hardhat, emergency backpack, and lamp, I'm about to get my first look at one of the largest infrastructure initiatives in Swiss history.

1.3 million trucks

The impetus for what is officially known as the New Rail Link through the Alps was a desire to cut in half the 1.3 million heavy trucks that ferry cargo through these stunning mountains every year. Today, there is century-plus-year old rail line that crosses through these high passes, but it forces trains to navigate hairy curves and climb hundreds of meters before heading right back down again.

By building the Gotthard Base Tunnel and its accompanying 15-kilometer Ceneri Base Tunnel (planned to open in 2019), Switzerland expects to reduce truck traffic to 650,000 a year and double cargo traffic from 20 million tons a year to 40 million tons. That's because the flat, mostly straight tunnel will be able to handle faster freight trains, and longer ones as well, with each train's capacity doubling from 2,000 tons to 4,000 tons. Maximum speeds will be as high as 155 miles an hour.

In addition, the tunnels will allow a better meshing of Swiss and Italian passenger train schedules, making more runs between Zurich and Milan possible.

Though the Ceneri tunnel is a major component of the larger project, it's the Gotthard tunnel, and its world-record length, that draws most of the interest. And for good reason. This is not just a single long tunnel. In fact, because safety and efficiency concerns led planners to design side-by-side one-way tunnels, the entire system, counting crossover tunnels, ventilation tunnels, and emergency stations, has required the excavation of 151.2 kilometers of Swiss Alp.

And because the goal of the project has been to reuse nearly 100 percent of the dirt and rock dug up, that's meant Switzerland has had a steady source of materials for making concrete and gravel, for filling old quarries and gravel pits, and for things like building dams. There was enough left over for the creation of island bird sanctuaries in Switzerland's Lake Lucerne, Bonanomi said.

Side-by-side tunnels

Rather than planning a single, two-track tunnel, Swiss planners decided on two that are parallel and one-way. This is partly for efficiency but also for safety: by having trains travel only in one direction, there is almost no chance for a calamitous head-on collision.

But the design is much more than just two side-by-side tunnels. There's also two crossover tunnels that will allow trains to switch sides in case of an accident or for maintenance, and two full emergency stop stations 20 kilometers apart where passengers can quickly and safely escape from a burning train into a special passageway that leads to a side tunnel where rescue will come quickly. The stations are big enough to handle up to 1,000 passengers, and take advantage of an overpressure system in which smoke cannot enter the escape passageways.

There's also separate passageways every 325 meters that bridge the 40 meters between the tunnels, allowing people aboard a stricken train to escape to safety if it can't make it to one of the emergency stations.

Finally, there are ventilation tunnels above the emergency stations designed to draw smoke from burning trains up through seven shafts at 250 cubic meters a second, a feature that is thought could clear the air in seconds in case of a conflagration and keep any people in the area safe from smoke inhalation.

At Sedrun, which is about a third of the way between the tunnel's portals at Erstfeld (to the north) and Bodio (to the south), there are twin 800-meter-tall shafts descending from a kilometer inside the mountain. One is for workers and other guests, and the other is for transporting equipment and other materials. Much of the machinery being used in the tunnels was sent down whole, but some was too big to fit in the elevators and had to be sent in parts and assembled below.

Multiple layers

Boring a 57-kilometer-long tunnel through an Alpine mountain is, of course, no easy task. And it wasn't a consistent one either. That's because there were many different kinds of rock to dig out. And each had its own personality. While much of the rock allowed for as much as 20 meters a day of excavation, some was so brittle--and required immediately shoring up with steel arches lest the tunnel collapse--that just a meter a day was possible.

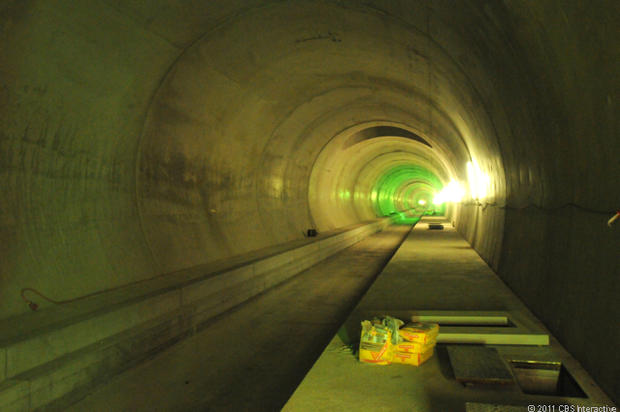

Once the tunnel was dug out, using a giant tunnel-boring machine, three layers are added to the new opening. The first is a drainage layer, then an impermeable, waterproof layer, and finally a protective membrane is added. Over that goes a layer of concrete that is smoothed out and then washed many times to ensure that the space is ready for the installation of electronics and other sensitive gear. One major advantage of smoothing out the interior of the tunnel is that it lowers air resistance, which in turn reduces the amount of heat trains generate while traveling through. In addition, the smooth lining is also expected to boost natural air circulation, cut humidity, and minimize groundwater seepage.

And because the tunnel must be completely dry before the electromechanical gear can be installed, Bonanomi said crews have brought down about 2.5 million square meters of waterproofing material so far.

Unfortunately, my visit came too late to see the tunnel-boring machine, as its work is done. These days, workers are busy adding the lining to some sections and will be doing so for the next year, Bonanomi explained, but otherwise, the major construction work is nearly done. Then comes installation of specialized electromechanical gear, testing, and other steps that will precede the tunnel opening for business.

'Can knock a train off the tracks'

While creating a separate crossover tunnel that trains can move onto in the case of maintenance or an accident might seem like a simple matter of constructing another section of tunnel, Bonanomi explained that there are additional complications.

Perhaps the most interesting, he said, is that so much air pressure would come through the crossover tunnel that if it weren't blocked off, "it can knock a train off the tracks," Bonanomi said. That means that at each end of the crossover sections, giant doors will be installed that will completely cut off the air. The doors will be so big that they will take as much as five minutes to open or close, and can be managed remotely from a control center at the tunnel's south portal.

As Bonanomi walked me through the tunnel, he was particularly excited to show me one specific element of the construction. This was effectively a large cavern for a train station for Sedrun being built just adjacent to the tunnel. This station, which would be called Porta Alpina, could handle passenger trains on the Zermatt to St. Moritz line and in theory could see as many as 3,000 people a day during ski season.

But this is nothing but a vision for the future. There are no plans to build out the train station any time soon. In fact, Bonanoni said, once the cavern is finished being excavated and cleaned out, it will be closed off. So why do it at all? Bonanomi said that the thinking was that if such a station was ever needed, it would be impossible to dig out the cavern later, so it was decided to invest the money now and do the major part of the work. It's "probably for the next generation," he said. But if it ever did open, it might well be the furthest underground train station in the world, as well as the highest elevation station on Earth.

Whether the station is built or not, however, the Gotthard Base Tunnel is one of the largest infrastructure projects Switzerland has ever seen, and if it works as planned, could teach the rest of the world a little about how to head off a developing problem. While the project is costing billions, it shouldn't incur any debt, and it is proactively dealing with a problem that, if unchecked, could have led to untenable traffic and growing costs for shipping cargo through central Europe.

But more than that, it's simply the world's longest tunnel. And it's 800 meters below the Alps. How cool is that?